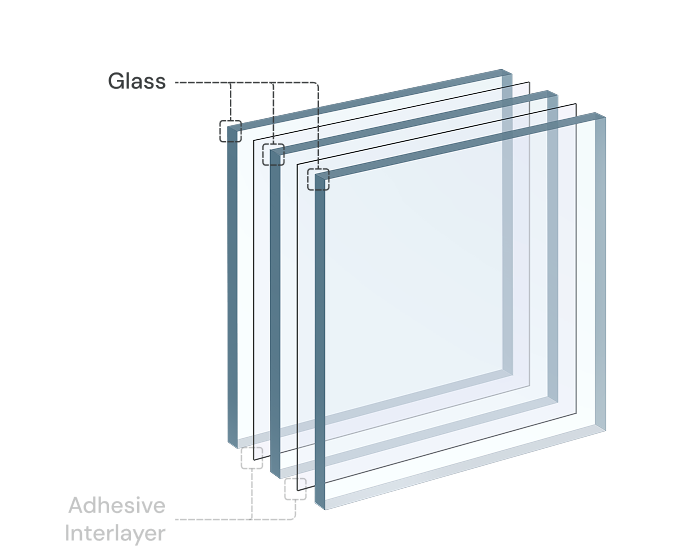

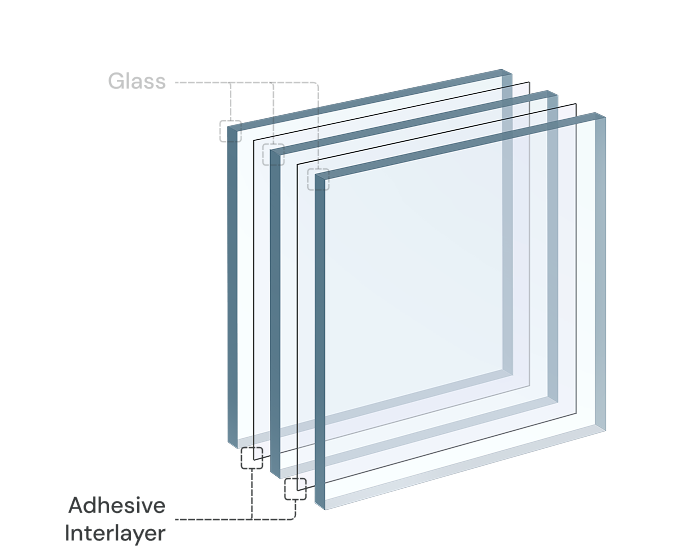

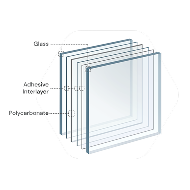

Glass Clad – All Glass

This low spall bullet-resistant laminate is a combination of glass and layers bonded together with adhesive interlayers. Most bullet-resistant glass clad products include a polycarbonate layer(s), but there is no polycarbonate layer in these laminates. The All Glass designs offer higher visual clarity when compared to constructions that include polycarbonate but are generally heavier than designs that incorporate polycarbonate.

This low spall product is fabricated with a layer of glass on the protection side (or interior surface) of the unit. The glass interior surface is a much harder surface than polycarbonate and therefore less likely to be damaged from improper cleaning or neglect. The benefit of glass clads include being glass cleaning user-friendly, excellent resistance to impact and penetration, and enhanced resistance to forced entry.

Make-Up Features

Ballistic Protection

The below chart refers to how much ballistic protection the Thompson Innovative Glass product provides, based on standardized testing. In the U.S., bullet-resistant glass is rated by UL 752 the standard for bullet-resistant materials set by Underwriters Laboratories (UL).

It defines testing methods and performance criteria for bullet-resistant glass, doors, panels, and other protective materials. and classified into a range of levels.

Get Expert Guidance on Defender Glass

Check with the Thompson Innovative Glass team for more details and options from our Defender line to find the right one for you and your application.

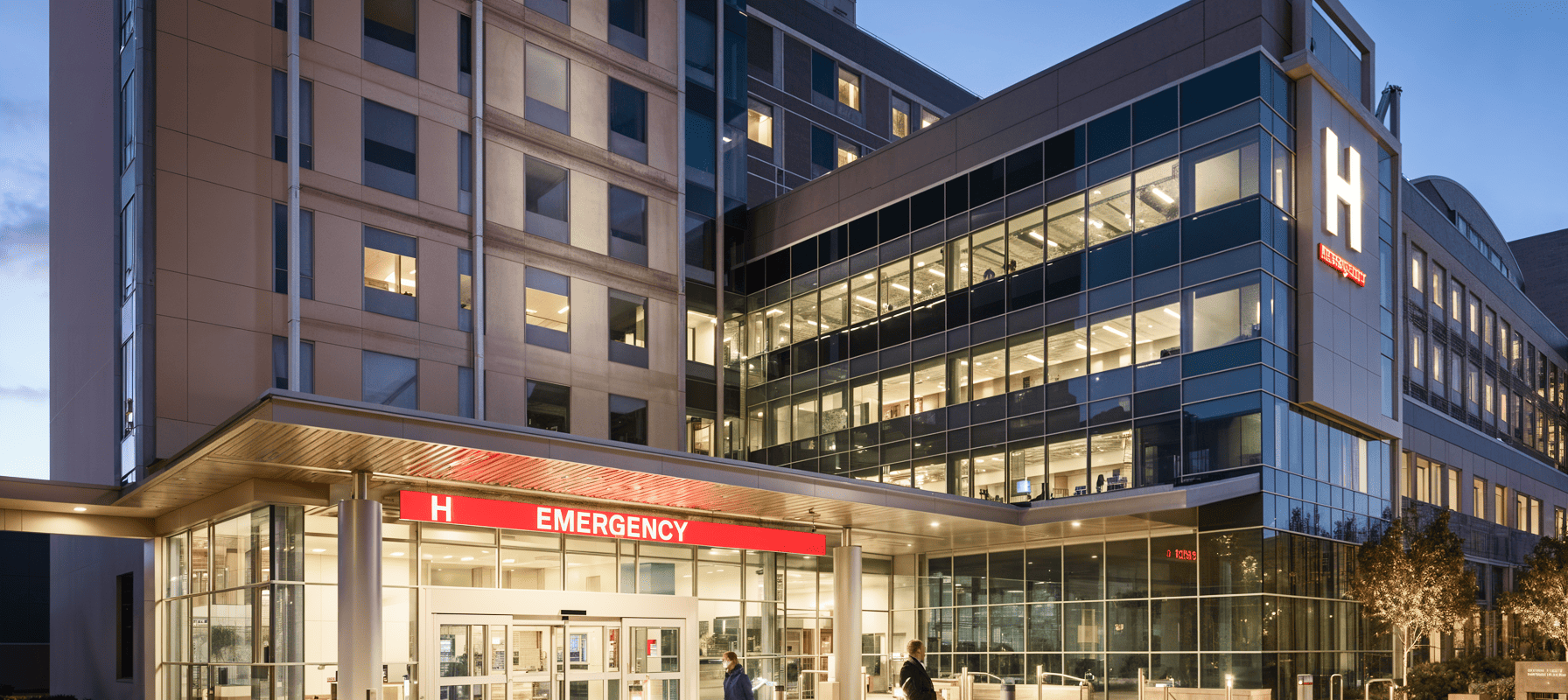

Applications-Security and Protection

Bullet-resistant and forced entry glass are critical components in protecting people and property across a wide range of high-risk environments. These specialized glazing solutions are trusted wherever enhanced security and peace of mind are essential, from public institutions to private facilities. Common applications include:

Places of Worship

Houses of worship often require protective glazing that balances aesthetics with security, helping safeguard congregants while maintaining natural light and architectural beauty.

Airports

Airports demand durable, high-performance glazing for passenger safety, blast resistance, and operational security in high-traffic terminals and control areas.

Schools

Security glazing enhances school safety by resisting forced entry and delaying intruders, providing critical response time without compromising light, visibility, or design.

Corporate Offices

Modern offices benefit from glass that provides energy efficiency and acoustic comfort—along with optional forced-entry and ballistic resistance for high-security needs.

Correctional Facilities

Glazing in correctional environments must meet rigorous standards for containment, safety, and visibility while withstanding impact and tampering.

Data Centers

Mission-critical data centers require fortified glass to secure sensitive infrastructure from both physical threats and unauthorized access.

Maximum Size

Maximum size for All Glass

72″ x 140″

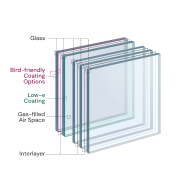

Your Guide to Bullet-Resistant Glass Options

Discover all bird-friendly glass options in our brochure.

Download Now

Frequently Asked Questions About Bullet-Resistant Glass

What is bullet-resistant glass?

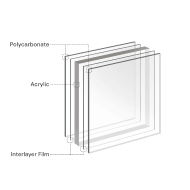

Bullet-resistant glass, also known as ballistic glass, is a type of reinforced glass designed to resist penetration from bullets. It typically consists of multiple layers of glass and polycarbonate materials, laminated together to absorb and disperse the impact of projectiles.

How does bullet-resistant glass work?

When a bullet strikes the glass, the outer layer absorbs the impact, while the inner layers dissipate the energy and prevent penetration. The polycarbonate layers add flexibility and strength, ensuring the glass remains intact even after repeated hits.

Is bullet-resistant glass completely bulletproof?

No material is entirely bulletproof. Bullet-resistant glass is designed to slow or stop specific calibers of bullets based on its rating. Over time or with repeated impacts, even high-rated glass may fail.

What are the levels of bullet-resistance?

Bullet-resistant glass is rated according to standards such as the UL 752 in the U.S. or EN 1063 in Europe. These levels indicate the glass's ability to withstand specific types of firearms and ammunition.

Where is bullet-resistant glass typically used?

- Banks and financial institutions

- Government buildings

- Schools and universities

- Retail stores (especially jewelry or high-value merchandise)

- Private vehicles and armored transport

- Security booths and checkpoints

Can bullet-resistant glass be installed in existing structures?

Yes, retrofitting is possible. Bullet-resistant glass can be customized and installed in existing frames, though structural modifications may be required for proper support.

Does bullet-resistant glass look different from standard glass?

Modern bullet-resistant glass is designed to look clear and similar to standard glass. Some thicker or higher-rated options may have a slight tint due to the layers of materials.

How thick is bullet-resistant glass?

Thickness depends on the level of protection, ranging from 0.25 inches (Level 1) to over 2 inches (Level 8). Higher levels of protection generally require thicker glass.

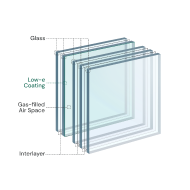

Can bullet-resistant glass be combined with other features?

Yes, bullet-resistant glass can include additional properties like:

- Energy efficiency with low-E coatings.

- Fire resistance for enhanced safety.

- Privacy options like tinting or one-way visibility.

And now via Thompson Innovative Glass- we offer Bird Friendly properties with Bullet Resistant Glass.

How much does bulletproof glass cost?

Bullet-resistant glass typically costs 100% to 400% more than standard commercial glazing.

Pricing varies based on:

- Threat level (UL 752 Level 1–8)

- Glass type (all-glass, laminated, or glass-clad polycarbonate)

- Size, thickness, and installation needs

While more expensive, it provides vital protection in schools, government buildings, banks, and other high-risk environments.

What is bulletproof glass made from?

Bullet-resistant glass is made from multiple layers of glass and plastic (polycarbonate or PVB interlayers). These layers absorb and slow down bullets, dispersing the energy and preventing penetration.

How is bulletproof glass made?

At our state-of-the-art facility in Jenison, MI, bullet-resistant glass is fabricated by:

- Tempering or heat-strengthening the outer glass for durability.

- Layering sheets of glass and plastic.

- Laminating them under heat and pressure in an autoclave.

- Precision bonding for optical clarity and resistance.

The result is a strong, transparent barrier that can stop bullets while still functioning as a window.

How thick is bulletproof glass?

The thickness varies by protection level:

- Level 1 (handguns): ~1-1/8" thick

- Level 3 (high-powered handguns): ~1-1/4" thick

- Level 8 (rifles): can exceed 2"+

We offer several options depending on the security need, including all-glass and hybrid glass-polycarbonate constructions.