Corporate Offices

Modern offices benefit from glass that provides energy efficiency and acoustic comfort—along with optional forced-entry and ballistic resistance for high-security needs.

Safety and security, whether at work, school or home has become a primary issue in our current landscape. Stakeholders are looking for bullet-resistant glass options that can meet various levels of security, and we’re happy that we can offer a vast range.

So whether you are designing for or installing at a bank, courthouse, embassy, retail operation, school, stadium, home or any other potential application looking for additional protective capabilities, we have the right product for you.

As an industry leader in advanced glass and lamination technologies, Thompson Innovative Glass offers customers throughout North America a full line of custom glass products. Our Quality Management System is ISO 9001:2015 Certified, delivering the highest quality products. The Defender glass series offers many choices and eliminates specific threats. Defender products offer different levels of bullet-resistance (BR). Our Defender BR-rated products are certified through third-party testing to meet and exceed industry standard UL safety code requirements for those levels.

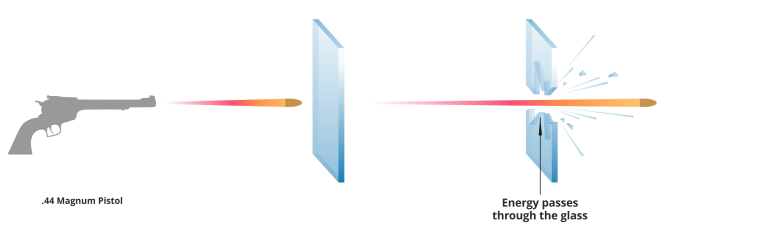

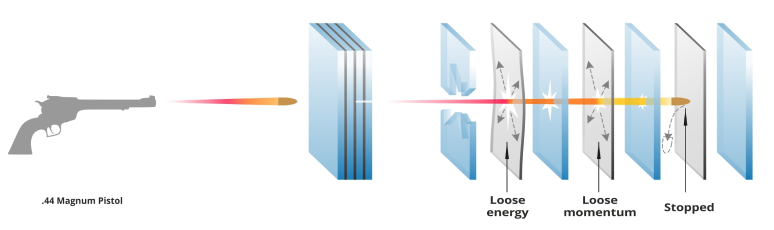

Bullet-resistant glass level ratings are specified by UL-752 based on the type of weapon used and the type and number of rounds fired. As weapons get larger, the ammunition gets bigger in size and also increases in speed, resulting in higher amounts of energy hitting the glass. Generally, more layers and thicker packages are needed to successfully dissipate that energy and stop the bullet.

In accordance with UL-752, bullet-resistant glass starts at level 1 and levels increase based upon weapon size and more powerful ammunition. Our Defender BR products follow these levels and, for many of these levels, offer no-spall and low-spall versions.

Defender bullet-resistant glass meets your need in the education sector as well as for retail and commercial applications. Additionaly, these products can be customized in various ways such as Low-E, tints or mirror glass. Defender supports Bullet-Resistant levels 1-8.

| Product | Weapon | Ammunition |

|---|---|---|

| Level 1 |

|

9mm Full Metal Copper Jacket with Lead Core |

| Level 2 |

|

.357 Magnum Jacketed Lead Soft Point |

| Level 3 |

|

.44 Magnum Lead Semi-Wadcutter |

| Level 4 |

|

.30 Caliber Lead Core Soft Point |

| Level 5 |

|

7.62mm Full Metal Copper Jacket Military Ball |

| Level 6 |

|

9mm Full Metal Copper Jacket with Lead Core |

| Level 7 |

|

5.56mm Full Metal Copper Jacket with Lead Core |

| Level 8 |

|

7.62mm Lead Core Full Metal Copper Jacket |

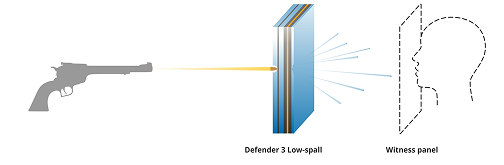

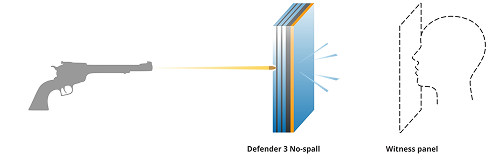

Any glass that gets hit by a bullet must absorb a large amount of energy in a split second. For certain glass make-ups, this may result in some very small fragments of glass coming off the witness-side (the inside) of the unit. These small fragments are referred to as ‘spall’.

Our Defender products offer no-spall (NS) and low-spall (LS) versions. To determine spall during the testing procedures, a witness panel, made of thin cardboard or aluminum, is placed behind the glass to determine how far glass fragments may travel without penetrating this panel.

Our low-spall products provide a cost-effective way to offer protection where no-spall is not required.

When it comes to security glass, two common approaches are laminated glass and film adhered to the glass. Both methods enhance the security and impact resistance of standard glass, but they differ in terms of construction, performance, and durability.

Laminated Glass is made by sandwiching layers of glass with a polyvinyl butyral (PVB) or other specialized interlayers. These interlayers bond the glass together, making it stronger and resistant to shattering. The main benefit of laminated glass is its strength and impact resistance. The interlayer makes the glass much harder to break, and even when cracked, the pieces stick to the interlayer, preventing easy entry. Laminated glass also features uniform performance across the entire surface, providing reliable protection against break-ins. Laminated glass can block harmful UV rays, reduces fading of interior furnishing and offers soundproofing benefits, reducing noise pollution.

Adding film is an aftermarket solution applied directly to the surface of existing glass. These films are made of a polyester or similar material that holds glass shards together if the glass is broken. While films can be applied to almost any existing glass, making them a versatile solution, they don’t provide the same level of protection against force as laminated glass. In addition, film can be scratched or degraded over time, reducing its effectiveness.

Even though safety is generally considered to be the number one priority of those looking for forced-entry protection or bullet-resistant glass, there are actually many additional benefits.

Provides time for occupants to react and first responders to arrive

Increases mental well-being of building occupants

Offers the same aesthetics as regular insulated glass

Allows damaged glass to be replaced at your convenience because it remains functional

Reduces sound

Provides immediate safety

Deters criminals after initial attempt at impact

Adds additional benefit of severe weather protection when used as an exterior application

Bullet-resistant and forced entry glass are critical components in protecting people and property across a wide range of high-risk environments. These specialized glazing solutions are trusted wherever enhanced security and peace of mind are essential, from public institutions to private facilities. Common applications include:

Modern offices benefit from glass that provides energy efficiency and acoustic comfort—along with optional forced-entry and ballistic resistance for high-security needs.

Security glazing enhances school safety by resisting forced entry and delaying intruders, providing critical response time without compromising light, visibility, or design.

Banks and financial offices rely on secure glazing for transaction windows, teller areas, and entry points to protect employees and assets.

Federal and municipal buildings require protective glazing that supports security mandates while upholding civic transparency and design intent.

Military facilities utilize protective glazing to defend against ballistic threats, forced entry, and blast events while maintaining structural integrity.

Healthcare environments use safety and security glazing in patient rooms, lobbies, and sensitive areas to enhance protection and hygiene without sacrificing light or openness.

Bullet-resistant glass, also known as ballistic glass, is a type of reinforced glass designed to resist penetration from bullets. It typically consists of multiple layers of glass and polycarbonate materials, laminated together to absorb and disperse the impact of projectiles.

When a bullet strikes the glass, the outer layer absorbs the impact, while the inner layers dissipate the energy and prevent penetration. The polycarbonate layers add flexibility and strength, ensuring the glass remains intact even after repeated hits.

No material is entirely bulletproof. Bullet-resistant glass is designed to slow or stop specific calibers of bullets based on its rating. Over time or with repeated impacts, even high-rated glass may fail.

Bullet-resistant glass is rated according to standards such as the UL 752 in the U.S. or EN 1063 in Europe. These levels indicate the glass's ability to withstand specific types of firearms and ammunition.

Yes, retrofitting is possible. Bullet-resistant glass can be customized and installed in existing frames, though structural modifications may be required for proper support.

Modern bullet-resistant glass is designed to look clear and similar to standard glass. Some thicker or higher-rated options may have a slight tint due to the layers of materials.

Thickness depends on the level of protection, ranging from 0.25 inches (Level 1) to over 2 inches (Level 8). Higher levels of protection generally require thicker glass.

Yes, bullet-resistant glass can include additional properties like:

And now via Thompson Innovative Glass- we offer Bird Friendly properties with Bullet Resistant Glass.

Bullet-resistant glass typically costs 100% to 400% more than standard commercial glazing.

Pricing varies based on:

While more expensive, it provides vital protection in schools, government buildings, banks, and other high-risk environments.

Bullet-resistant glass is made from multiple layers of glass and plastic (polycarbonate or PVB interlayers). These layers absorb and slow down bullets, dispersing the energy and preventing penetration.

At our state-of-the-art facility in Jenison, MI, bullet-resistant glass is fabricated by:

The result is a strong, transparent barrier that can stop bullets while still functioning as a window.

The thickness varies by protection level:

We offer several options depending on the security need, including all-glass and hybrid glass-polycarbonate constructions.

We know you have choices when it comes to forced-entry protection and bullet-resistant glass. So what makes Thompson's Defender glass unique?

As a full-service glass fabricator, Thompson Innovative Glass offers a full line of glass products including insulated glass and laminated glass. This mean that projects requiring safety glass and 'regular' insulated glass can get it all from the same source.

Unique in the marketplace, we can offer bullet-resistant rated glass that is insulated and will fit most window frame systems, combing safety with comfort and energy savings.

Because we are a full-service fabricator, we can offer customized safety glass. Customizations can include low-E, tinted glass or one-way mirror glass.

With a large team of dedicated employees, Thompson I.G. has the flexibility to pool manpower where most urgently needed. This results in faster lead times for you when you need your glass ‘yesterday’.

As a full-service fabricator, we work on ‘regular’ insulated glass as well as on specialty glass products like bullet-resistant glass. This translates to zero downtime and lower overhead, resulting in very competitive pricing for you!

With state-of-the-art dedicated clean rooms and multi-step inspection procedures, we guarantee high-quality.

We partner with our customers. We offer advice, on site visits and informational presentations to make sure that you end up with the best possible solution for your project.